Digital technology

How has digital technology evolved in the Company over the past 20 years?

Digital technology is an important part of the Company’s Production and Technical Development Strategy. It is aimed at reducing costs and optimising inefficient production, while concentrating efforts on profitable assets. Committed to operational excellence, the Company leverages information support to introduce modern approaches to operational management and planning based on ever‑changing input data, deploys various digital technologies, and makes sure its employees are being trained to improve their competencies: since 2014, Nornickel has been using SAP ERP to automate key business processes across its core production assets, and since 2015, the Company has been running a 10‑year Technology Breakthrough programme designed, among other things, to roll out modern digital technology in production and unmanned mining.

Relevant UN SDGs

Related federal projects

Key initiatives and focus areas

By developing and deploying digital solutions across its business processes, the Company lays the groundwork for building a high‑tech business and contributes to greater industrial safety, operational efficiency, and quality of life for local communities. On an ongoing basis, the Company implements IT initiatives to support its key business operations and develop technological sovereignty.

Driven by external challenges, in 2023 the Company updated its Functional Information Technology Strategy focusing on reliability and accessibility, adaptability, and achievement of technological independence as the key strategic benchmarks. Strategic objectives include faster decision‑making, attracting the necessary competencies, and ensuring smooth operation of the IT landscape in the process of its transformation.

We see digitalisation as a performance improvement tool currently used everywhere – from adjusting the key business processes (procurement, finance, production) to implementing the autonomous and remote asset management systems.

Alexey Lenkov,

Head of Office, Norilsknickelremont

(length of service with the Company — 24 years)

In line with Nornickel’s strategic IT priorities, in 2023 the Company continued efforts to ensure its technological independence, including over 20 major initiatives aimed at renovating the IT landscape, which cover the replacement of more than 50 imported and import‑dependent information systems, as well as infrastructure components, operating systems, database management systems, and application software.

To ensure the Company’s technological independence in 2023:

- consistent efforts were taken to manage risks in the IT landscape to ensure the continuity of the Company’s current operations;

- the life cycle of each component of the IT landscape was assessed with the degree of its impact on the core business and priorities determined: approximately 80% of domestic IT infrastructure solutions were selected or the development of in‑house products was launched for solutions that are unique both for the market and for the Company;

- a pilot testing phase of selected solutions was launched to last until the end of 2024. It will serve as the basis for detailed plans showing how technological independence can be achieved for the greatest part of the Company’s IT landscape;

- a technological radar of global trends was prepared, a unified software repository was launched, an update checking and installation process was built, and a list of programmes approved for installation and use was created;

- target architectures were developed for key business areas such as industrial automation, logistics, economics, finance, and personnel management;

- in 2024, the Company plans to launch pilot implementation of a Linux‑based core of multifunctional infrastructure solutions, which will test the compatibility of the main components of the Company’s future IT infrastructure.

Development of enterprise data centre cluster in Moscow

Due to increased information storage volumes, in 2023 the Company selected and organised a new site for its main data centre in Moscow to enable the implementation of the Company’s strategic plans on a 10‑year horizon.

Real‑time migration of information systems to the new data centre does not affect any business processes as timely planning helps manage the pace of relocation and minimise the risks of information system failure. As at the end of 2023, 40% of equipment has migrated. The relocation is to be completed by May 2024.

Development of IT infrastructure monitoring systems

Monitoring IT infrastructure and business applications is one of the key elements to ensure stable operation of the Company’s assets. Continuous monitoring of key indicators enables support services to promptly identify problem areas, prevent possible information system downtime, and identify potential performance boost areas across the IT landscape.

In 2023, the Company continued to develop its corporate IT monitoring service: the number of IT systems under monitoring increased by 20% to exceed 20,000 with more than 3 mln behaviour metrics collected and analysed around the clock, which makes it possible to timely make informed decisions with respect to IT service management.

Server room upgrades across production sites

To maintain the uninterrupted operation of information systems and automated process control systems at its production sites, the Company continues to take steps to improve the reliability of critical IT infrastructure. With more than 70 server rooms already revamped, another 190 await their turn to be upgraded.

Process data network upgrades

In 2023, the Company continued building a dedicated data network and upgrading the existing underground backbone data network. Going forward, the high‑speed network will drive the development of next‑gen production systems, including by providing the necessary IT infrastructure for the unmanned mining solutions and remotely controlled production equipment. In addition, the network will allow exchanging data with the automated process control system (APCS) and safely connecting to the unified network of new shops at Kola MMC, Medvezhy Ruchey.

Industrial automation systems

Technological independence is an important driver of industrial automation system development at the Company. For this purpose, in 2023 Nornickel undertook the following:

- made a list of imported APCS software used at the Group’s assets;

- organised a distributed network of laboratories to test communication compatibility of SCADA systems with programmable logic controllers (PLC) to make sure the approved solutions can be integrated into the existing IT landscape;

- worked together with the manufacturers of domestic SCADA systems and PLCs to eliminate identified limitations, and prepares virtual infrastructure for subsequent testing subject to the requirement to use system components free from sanction restrictions (CoreIT);

- continued efforts to bring domestic APCS solutions in compliance with information security requirements of the Company;

- organised a series of induction training sessions to introduce staff to the Company‑approved solutions, and developed specialised need‑based training courses focusing on the existing equipment available in the online and offline formats;

- sent its experts to the working group led by the Ministry of Industry and Trade of the Russian Federation to create an open APCS (contribution to drafting technical requirements for the individual components of an open APCS).

The Company launched a project to develop and deploy an automated mining and geological data processing and analysis system (MinePRO).

This IT product was presented at the 19th MINEX Russia 2023 Mining Forum, where it was awarded a finalist in the MineDigital category.

Measurement consistency

In 2023, the Company put into operation a locally produced automated metrological service management system (NERPA). The system enables a unified, Company‑wide approach to metrological accounting and control over measuring instruments, offers a uniform approach to verification and calibration scheduling, reduces time for work planning and execution, and use of measuring instruments with expired verification and calibration periods, and tightens control over the condition and use of measuring instruments. In 2023, the Company assessed solutions offered by 27 domestic manufacturers, reviewed the available measuring instruments for the possibility of pilot operational tests in real production conditions, made a register of domestic measuring instruments publicly available on the corporate portal in the Metrological Service section, held the R&D Panel fixing the adopted approach to manufacturer evaluation, as well as the register of measuring instruments and domestic manufacturers to be considered as first priority when choosing the measuring instruments.

Production video analytics

Nornickel is actively engaged in developing video analytics and machine vision systems to solve production tasks, improve environmental efficiency, and ensure labour safety.

During the reporting year, the Company updated its automated system for monitoring the use of personal protective equipment (PPE) by adding a module for biometric identification of non‑compliant cases at GRK Bystrinskoye. The system was found efficient during industrial operation detecting more than 89% of PPE use violations and boasting over 70% accuracy in non‑compliance identification. The solution is integrated with the automated personnel management system (APMS) and access control and management system (ACSS) for greater industrial safety control.

Another industrial safety upgrade included implementation of a prototype of a gantry crane area control system. The system is expected to be expanded to add 15 cranes of GRK Bystrinskoye. The system uses laser beams to project the danger zone onto the crane area, thus controlling the presence of people in the cargo handling area for improved industrial safety.

Video analytics was also used as part of a video analysis system introduced to analyse thickener overflow turbidity (Mutnometer), which made it possible to leverage AI‑based solutions to record leaks of solid product, foam, contamination, and overfill of the drain. The system helps improve thickener performance and minimise losses.

The Company has also developed a software package to monitor the operation of mining equipment, including mining dump trucks, load‑haul‑dumps, mine cars, tippers, and self‑propelled drilling rigs. Currently in the testing phase, the project seeks to improve the efficiency of mine management and dispatching, and enables accurate tracking of activity and equipment workload based on video from cameras. The software includes tools for video markup allowing to speed up the process of data set collection and improve accuracy due to the involvement of mine experts. In 2023, four prototypes were developed and are planned to be tested at Polar Division’s mines.

The machine vision‑based Ore Flow project implemented at Kola MMC has unlocked new opportunities for improving the underground rail transport and ore logistics management system. Using both fixed cameras and those on vehicles, the system monitors underloading, sticking, fractional analysis, and water content of ore. Ore quality can also be assessed using infrared technology, thus allowing analysis in dusty environments. The system also identifies the location of equipment in the mine by monitoring the pick‑up and dumping points, and transportation routes. Severny Mine (Kola MMC) has integrated all the developed detection models into a single solution that is currently undergoing pilot tests. The system is expected to be rolled out at Polar Division’s mines.

An important aspect of video analytics evolution at Nornickel in 2023 was the launch of the development of the Company’s own NVi platform mainly focusing on accelerating the creation and integration of computer vision systems within the Company. NVi facilitates the development process by enabling the use of standard blocks and unifying processes while leveraging accumulated experience and expert knowledge.

Data Lake ecosystem

The Data Lake ecosystem serving as a starting point for digitalising business processes at the Company is a scalable platform that in the long term will allow the storage, analysis of Group‑wide data, and additional synergies through the enrichment of external systems with new data. The existing solutions offered by the system allow for efficient processing of data from equipment sensors and integrate machine learning models enabling analytical BI‑based reports.

In terms of artificial intelligence, the Data Lake ecosystem serves as a single platform for all artificial intelligence models, digital twins, and advisor systems under development. The in‑house machine learning environment (ML‑environment) deployed on the basis of server infrastructure is already in use helping accelerate the implementation of digital projects and reduce the analytical load on production control and dispatching systems.

In order to increase the speed of artificial intelligence developments, an enterprise‑wide MLOps process has been implemented to reliably and efficiently deploy and maintain machine learning models in production.

The ML environment is available to both internal AI developers and development teams of external contractors.

The ecosystem helps solve business cases for various segments. For example, machine learning is currently used to improve the quality of nickel produced through electrowinning at Kola MMC, while specialised models were developed to predict impurities in finished products supporting nickel production in the Plating and Superalloys segments.

In 2023, the Data Platform project landscape based on Russian Arenadata software was successfully deployed helping ensure multi‑landscape in the ecosystem.

The deployment of geo‑distributed Data Lake infrastructure at production sites is planned for 2024, which is the next stage in the development of the data driven approach in the Company.

In order to replace foreign IT solutions and develop new digital products, Industrial Competence Centres (ICC) have been operating in Russia since 2022, bringing together developers, manufacturers, and customers for the development of key economic sectors.

Metallurgy ICC

As an anchor customer of the Metallurgy ICC, Nornickel is in charge of three key mining projects: the Mining and Geological Information System, the Mining Operations Planning AMS, and the Underground Mining Control. Norsoft, a specialised company, was established in 2023 to develop IT products and has, as at the year‑end, already completed prototype development. Norsoft brought IT products together under the new MAGMA brand and developed an approach to product commercialisation with the involvement of independent commercial companies. The results were presented to the industry community and production site experts (more than 130 representatives of Russian mining and metallurgical companies) at the end of 2023.

Plans for 2024 include completing the development of the core functionality of industry‑specific mining solutions; 2025 is about to see joint testing of the prototypes and piloting of IT products at the production sites of Nornickel and co‑customers (other industry players).

Environment ICC

Federal lawsFederal Law No. 7-FZ On Environmental Protection dated 10 January 2002 require that companies causing negative environmental impact equip sources of pollutant emissions at the first category facilities with automatic systems of measuring and recording emissions. Russia uses foreign‑produced systems of automated emission control, which may entail the delivery time and equipment cost risks.

Since 2023, Nornickel, Norsoft, and Digital Corporate Technologies, a developer of innovative software solutions, have been working on a unique joint project to create an alternative automated measurement system to keep record of production emissions based on the use of process digital twins (PEMS). The Government Commission recognised the project as particularly significant putting it on the List of approved projects to replace foreign software with Russian solutions. Included in New Industrial Software, a high‑tech development roadmap, the project has the first‑order implementation priority and a high environmental significance.

In 2023, Nornickel started using an automated system for managing its corporate process model (the “System”). This System is a proprietary solution of the Company featuring a web interface implemented through a flexible and efficient technology, and software deployed across several relevant platforms.

It serves as a single entry point for obtaining real‑time information about the Company’s business processes, their owners, and content. The System encompasses the full cycle of business process regulation, including description of the business process in the form of a data sheet, approval, and sign‑off with an advanced electronic signature.

The System helped integrate business process descriptions into the Company’s unified information space, and ensure bilateral synchronisation with the automated risk and KPI management systems and the regulatory database; the innovative approach to regulation reduced labour inputs in the search and update of business process information.

Digitalisation and development of corporate business processes

- improve the automation of certain document flow processes: due to the algorithmisation and robotisation of some accounting functions, some processes became 13 times more efficient;

- convert contracts into electronic form in a pilot mode (over 58% of paperless contracts) and reduce the signing time to 30 minutes.

The Integrated Document Management programme was awarded the Best Implementation prize at SCB Kontur’s Electronic Document Management Award competition.

In 2023, the Company deployed a personnel electronic document management (PEDM) system switching it to the locally‑produced Directum RX platform. The PEDM will minimise the use of paper documents, increase labour productivity of the personnel management staff, harmonise the technologies used in business process paperwork, and provide an opportunity to forecast and quickly respond to internal and external changes related to the document flow system supporting relevant business processes.

Another example of the transition to electronic document management in the Company, and, in fact, its transformation due to the transition to new forms of interaction, is the elaboration together with the Government of Russia of data marts designed to shift away from “electronic documents” in favour of “data marts”, an innovative approach to information management within the framework of the upcoming national project Data Economy.

In 2023, the Company developed and deployed the Budgeting 2.0 module of the Budget Planning IS. It enables calculation of capital project budgets, which inherently serve as sources of data for investment project monitoring, investment committees and subcommittees.

In 2023, the IT project to develop and implement an electronic queue management system in the Norilsk branch office of NN‑Sputnik was completed, which improved the quality of customer service and reduced the time required to generate consolidated reports.

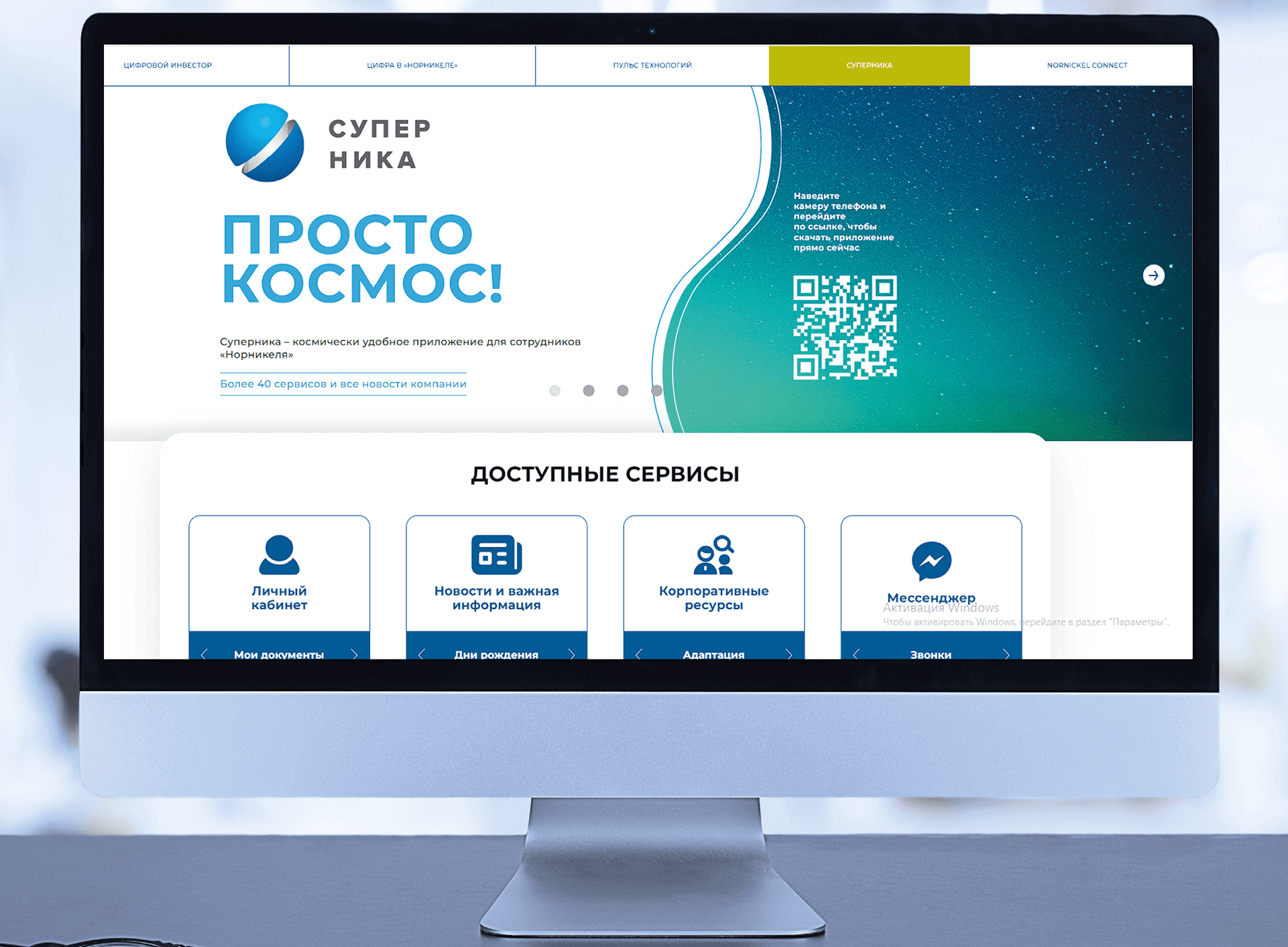

The Supernika system has been launched and is available for connection in all structural divisions of the Company, with 40,000 employees of the Group from 22 cities already using the system in 2023. This is Russia’s first corporate app featuring both modern approach to business process management and usability of digital services of the Company. All users can use personal and corporate mobile devices to access the corporate messenger, employee’s personal account, corporate portal, and a number of other functions.

In addition, in 2023 the Company renovated the Tableau‑based management data visualisation system transferring data to two systems, namely FINE BI and Forsight, to minimise risks. The reporting year also saw renovation completion of the portals of the Legal Department and the Corporate Trust Line undertaken mainly to improve information security in terms of using the latest software, ensuring stable performance, and the potential for further development of portals.

Digitalisation and financial services

In 2023, the Company implemented a project aimed at transitioning from the electronic banking system, which required transferring payment registers between systems via files, to direct seamless integration where payment orders and other financial messages are sent directly from the ERP system to the bank using a specialised transport system, which reduces the risk of errors and significantly speeds up the payment process.

In addition, an important result of the integration is the automatic receipt of interim and final bank statements, which allows for prompt receipt of the cash flow and account balance information.

Concerning Digital Treasury development, in 2023 the Company continued to develop its own dynamic discounting platform and automated several financial tools in the ERP system, setting the stage for rolling them out and unlocking additional economic benefits.

The Company ensures maximum cooperation with tax authorities. Following the transition to the real‑time tax monitoring system, over 97% of the Group’s turnover has been monitored by the tax authorities in real time since 2023.

Improving IT infrastructure reliability at the Norilsk Airport

IT infrastructure is one of the key elements of ensuring uninterrupted operation of automated systems at an airport such as flight control, passenger check‑in, baggage handling, announcements, security, access control, explosives detection, etc.

To ensure uninterrupted operation of IT infrastructure at the Norilsk Airport, its upgrade was launched in 2023. The upgrade was planned considering both the solutions currently available on the IT market and regulator requirements. The project will be delivered using locally produced equipment and software. The upgrade is expected to be completed in Q1 2024.

Fibre optic communication line in the Norilsk Industrial District

In order to support the Company’s production needs with high‑speed communications and improve the quality of life in the Norilsk Industrial District by providing broadband Internet access, improving the quality of services, expanding the range of communication services provided, and improving the quality of public services, as well as building a platform for further development of the communications infrastructure of the Taimyr Peninsula, the Company constructed a fibre optic communication line (FOCL) along the 956 km Novy Urengoy–Norilsk route. Since 2017, high‑speed internet is provided both for the needs of the Norilsk Industrial District and for those residing along the constructed fibre optic line.

To improve the reliability of the communication line, in 2023 work was completed to reserve sections of the Norilsk–Igarka and Vankor field–Novy Urengoy routes, as well as to strengthen the section of the route along the banks of the Yenisey River by laying fibre optic cable in cases using horizontal directional drilling.

The line is maintained by Nornickel’s own operation service consisting of a call centre and a single network management centre, as well as field crews staffed by highly qualified personnel experienced in working in challenging conditions and fitted with special equipment and a fleet of custom‑made all‑terrain vehicles. There is also a construction and installation department of about 200 people and a dedicated fleet of construction equipment. From 2023, the use of unmanned aerial vehicles is being tested to improve the efficiency of preventive maintenance and monitoring of the highway and nearby facilities.

Given the steps taken to improve the reliability of the communication line, the current service level is not less than 99% and the emergency recovery takes no more than 72 hours.

To improve the quality of communications given the growing demand across the Norilsk Industrial District, work was carried out to expand the bandwidth five times, from 40 to 200 Gbps, which made it possible to increase traffic in client communication channels up to 95 Gbps.

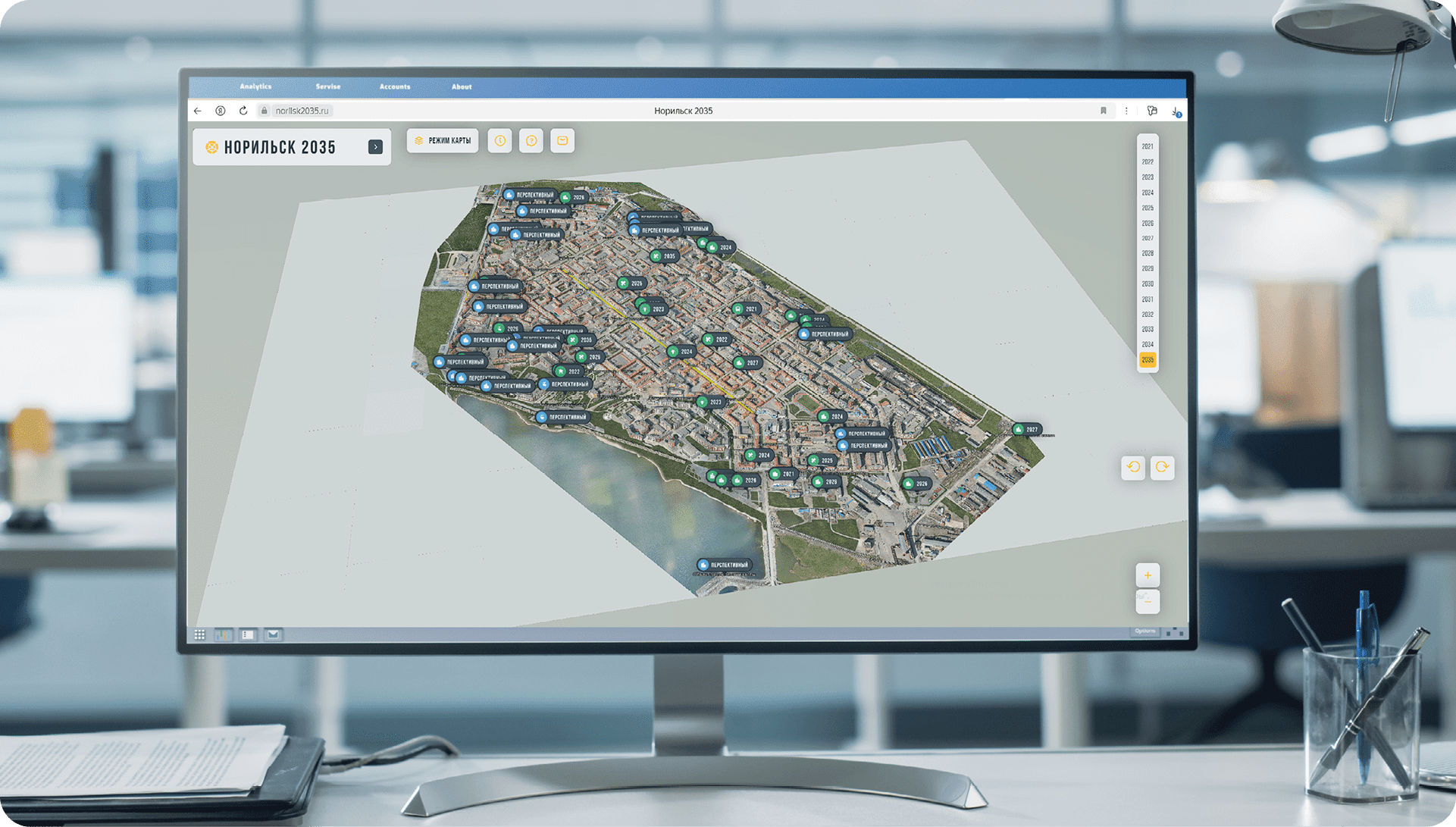

Digital renovation platform for Norilsk

At the end of 2023, the Norilsk Development Agency, supported by the city administration and Nornickel, launched Norilsk 2035, a web platform dedicated to the renovation of Norilsk. Based on the immersion principle, the digital product gives a comprehensive idea of how the Polar city will be renewed and allows getting general information about urban change projects, or deep diving into a particular renovation project. The core of the online platform is an interactive 3D map that replicates in detail the entire city infrastructure.

The digital city model can be viewed in two modes:

- Facilities by district presenting all renovation facilities in Norilsk, from construction of residential buildings and social facilities to land improvement and landscaping;

- Overview map of renovation facilities familiarising with the scale of urban renewal as a whole. In this mode, renovation sites are shown with general information about the facility, the estimated year of completion, and progress (started/in progress/completed).

The map allows moving to 2035 and seeing how Norilsk is changing over years.

As at the end of 2023, maps of all territories have been uploaded to the platform: Central District, Talnakh, Kayerkan, Oganer, and Snezhnogorsk with 3D models of all residential buildings, social, cultural, and other facilities, both existing and planned for construction, reconstruction, and improvement until 2035. Going forward, the developers plan to add other significant changes in the city that are not included in the Comprehensive Plan of Social and Economic Development of Norilsk through 2035, but are important for local residents.